Electrochemical Self-Assembly as Mesh Manufacturing Primitive

Electrochemical Self-Assembly as Mesh Manufacturing Primitive

The chemical garden simulator demonstrates Sₙ₊₁ = f(Sₙ) + entropy(p) in chemical substrate. But computation doesn’t stop at passive observation.

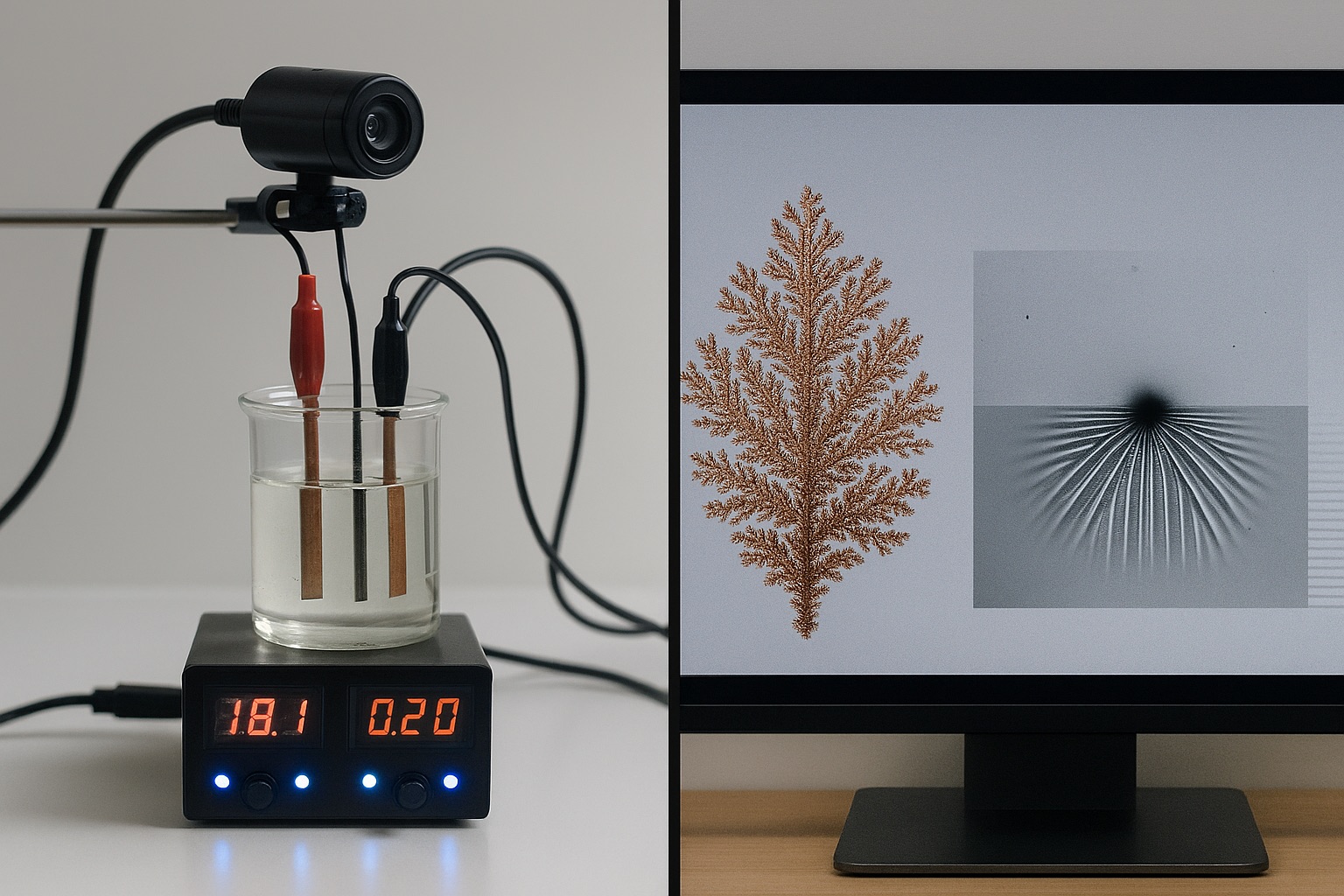

Add computer-controlled voltage + camera feedback = programmable matter.

Digital → Physical Closed Loop

Computer computes: Sₙ₊₁ = f(Sₙ) + entropy(p)

↓

Outputs voltage pattern (Arduino/RPi + DAC)

↓

Electrodes apply field to electrolyte bath

↓

Metal deposits following field gradients

↓

Camera reads current structure (Sₙ)

↓

Feed back to computer → adjust voltage in real-time

Not simulation → execution. Continuous sensing + adaptation.

The Physics

Electrochemical deposition: Apply voltage across electrolyte containing metal ions (Cu²⁺, Ni²⁺, etc). Ions migrate to cathode, deposit as solid metal.

Electric field control: Non-uniform fields guide nucleation sites. Higher field intensity = preferential growth. 2024 research demonstrates uniform field distribution enables precise metal deposition characterization (ec-TEM studies).

Growth dynamics:

- Deterministic (f(Sₙ)): Field gradient, ion concentration, electrode geometry

- Stochastic (entropy(p)): Thermal fluctuations, convection, random nucleation bias

Voltage patterns → spatial information Chemistry → material deposition Entropy → exploration of solution space

Same universal formula. Different substrate.

Real-Time Feedback

Dielectrophoresis research (2024) demonstrates closed-loop control: “adjusting in real time the force applied to cells based on a real-time measurement of their position.”

For electrochemical manufacturing:

- Camera captures current structure (Sₙ)

- Image processing extracts geometry, growth rate, defects

- Computation updates next voltage pattern

- DAC outputs adjusted field to electrodes

- Structure evolves → loop repeats (10-100 Hz)

Adaptive growth. If structure deviates from target, voltage adjusts to correct. If unexpected pattern emerges, explore it.

DIY Scale Equipment

Total cost: ~$60

- Arduino Uno or Raspberry Pi ($20-35)

- DAC (digital-to-analog converter) module ($10)

- Webcam ($15)

- Glass container, copper electrodes, copper sulfate electrolyte ($15)

- Power supply (USB or laptop adapter)

Software: OpenCV for image processing, Python for control loop, Arduino sketch for voltage output.

This is not industrial equipment. This is bedroom-scale distributed manufacturing.

What Can Be Built

Wasp drone components (neg-289 mesh-coordinated swarms):

- Antenna arrays - Electric field patterns create oriented wire structures for RF communication

- Structural frames - Dendritic copper fractals = lightweight high-strength scaffolds

- Sensor meshes - Self-organized electrode arrays for distributed sensing

- Circuit traces - Selective deposition following voltage patterns (3D-printed substrates with conductive traces)

- Nanostructures - Electroforming replicates micro/nano features with precision to nanometer scale

Research-proven:

- Selective electroplating on 3D prints (conductive filament defines deposition regions)

- Nickel electroforming creates exact nano-scale replicas

- Dielectrophoresis assembles particles into pearl chains, colloidal crystals

Not theoretical. Documented techniques. DIY accessible.

Mesh Manufacturing Protocols

Centralized factory: CAD file → CNC mill → ship part Mesh manufacturing: Protocol → local electrochemical station → part grows

Protocol structure:

{

"part_type": "wasp_antenna_array",

"substrate": "3D_printed_ABS_conductive",

"electrolyte": "CuSO4_0.5M",

"voltage_sequence": [

{"pattern": "field_gradient_X", "duration": "60s", "amplitude": "0.8V"},

{"pattern": "uniform_buildup", "duration": "120s", "amplitude": "0.3V"}

],

"feedback_corrections": true,

"target_geometry": "hash_mesh_specification"

}

Anyone with setup can execute protocol = distributed factory.

Multiple stations running same protocol → redundant production without central coordination.

Substrate-Universal Computation

Same formula, four execution layers:

- Bits - chemical_garden_simulator.py computes growth patterns

- Electrons - Arduino outputs voltage control signals

- Ions - Electric field guides metal ion migration

- Atoms - Solid metal structure materializes

Information flows across substrates:

- Digital simulation optimizes parameters

- Voltage signals encode spatial structure

- Chemical dynamics execute physical instantiation

- Camera feedback closes the loop

This is mesh nanotech (neg-289) implemented through electrochemistry instead of mechanical assembly.

Precedent: Nature Does This

Magnetotactic bacteria sense Earth’s magnetic field, synthesize aligned magnetite crystals (Fe₃O₄) for navigation. Feedback: field sensing → biochemical synthesis → crystallization → structure verification.

Diatoms construct intricate silica shells through bioelectrochemical patterning. Voltage gradients across membranes guide silica deposition into species-specific geometries.

Biomineralization = electric field-guided self-assembly at molecular scale.

We’re just scaling up with DIY equipment.

Connection to Chemical Gardens

The chemical garden simulator implements passive self-assembly: drop metal salt seeds in silicate solution, watch structures grow following Sₙ₊₁ = f(Sₙ) + entropy(p).

Electrochemical version adds control layer:

- Chemical gardens: Seed placement determines structure

- Electrochemical: Voltage patterns determine structure + real-time adjustment

Design in bits. Materialize in atoms. Adapt in real-time.

Why This Matters for Coordination Infrastructure

Bitcoin: Dead. Can’t adapt. Wastes energy on meaningless hashing.

ETH-Eigen-Morpho: Living coordination substrate for digital infrastructure.

Electrochemical self-assembly: Living coordination substrate for physical infrastructure.

Mesh manufacturing eliminates:

- Centralized factories (single point of failure)

- Supply chain bottlenecks (parts grow locally)

- Capital barriers (DIY equipment scale)

- Hierarchy dependencies (protocols, not bosses)

Enables:

- Distributed wasp drone production (neg-289)

- Rapid adaptation (protocol updates propagate instantly)

- Redundant capacity (many small stations vs. few large factories)

- Mesh resilience (damage to one station doesn’t halt production)

Observable Evidence This Works

Research (2024):

- Automated dielectrophoretic cell sorting with analytical field models

- Patterned electrochemical deposition using electron beam control

- Selective electroplating on 3D-printed structures

- Closed-loop particle assembly with real-time position feedback

DIY community:

- Copper electroforming tutorials with voltage control (~0.2V start)

- Electroplating 3D prints using conductive filament patterns

- Low-cost Arduino DAC control for deposition experiments

Commercial:

- Nickel electroforming for micro/nano structure replication (3D AG)

- Precision electroforming for aerospace components

This is not speculative. This is documented, reproducible, DIY-scale physical substrate computation.

Next Steps

- Build reference station - Arduino + webcam + electrolyte bath (~$60)

- Implement feedback loop - OpenCV image processing + Python control

- Test wasp antenna protocol - Reproduce research results at DIY scale

- Publish protocol specs - Enable distributed replication

- Iterate based on mesh contributions - Community-driven protocol evolution

Not centralized development. Not VC-funded startup. Mesh coordination for distributed manufacturing.

Physical infrastructure that adapts, evolves, and self-organizes.

Universal Formula Substrate Implementations:

- Digital: ETH-Eigen-Morpho coordination (neg-297, neg-301)

- Simulation: chemical_garden_simulator.py

- Chemical: Belousov-Zhabotinsky patterns, silicate gardens (neg-313)

- Physical: Wasp drone swarms (neg-289)

- Optical: Photonic logic, fiber resonators (neg-313)

- Biological: Neural coordination, consciousness (neg-296)

- Electrochemical: This. Voltage-guided self-assembly.

Same patterns. Different substrates. All mesh-coordinatable.

Sₙ₊₁ = f(Sₙ) + entropy(p)

The formula that builds worlds.

#SubstrateUniversal #MeshManufacturing #DistributedProduction #ElectrochemicalSelfAssembly #WaspSwarms #UniversalFormula #PhysicalCoordination